Sjoberg Catalog

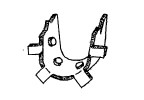

Strain Reliefs

Applications:

Strain reliefs thimbled aluminum clip prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Approximate Diameter >> in [Imperial]:

0.250 x 0.125

Material:

Aluminum

Minimum Order:

1

Thickness >> in [Imperial]:

0.055

Width >> in [Imperial]:

0.140

Approximate Diameter >> in [Imperial]:

0.170 x 0.080

Length >> in [Imperial]:

0.340

Material:

Brass

Minimum Order:

1

Thickness >> in [Imperial]:

0.032

Applications:

Hog Ring prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Approximate Diameter >> in [Imperial]:

0.100

Material:

Steel

Material Diameter >> in [Imperial]:

0.060

Minimum Order:

1

Approximate Diameter >> in [Imperial]:

0.437

Length >> in [Imperial]:

0.360

Material:

Brass

Minimum Order:

1

Thickness >> in [Imperial]:

0.040

Approximate Diameter >> in [Imperial]:

0.375

Length >> in [Imperial]:

0.360

Material:

Brass

Minimum Order:

1

Thickness >> in [Imperial]:

0.040

Approximate Diameter >> in [Imperial]:

0.250

Length >> in [Imperial]:

0.220

Material:

Brass|Steel

Minimum Order:

1

Thickness >> in [Imperial]:

0.032

Approximate Diameter >> in [Imperial]:

0.200

Length >> in [Imperial]:

0.281

Material:

Steel

Minimum Order:

1

Thickness >> in [Imperial]:

0.032

Approximate Diameter >> in [Imperial]:

0.190

Length >> in [Imperial]:

0.281

Material:

Steel

Minimum Order:

1

Thickness >> in [Imperial]:

0.050

Approximate Diameter >> in [Imperial]:

0.200 x 0.100

Length >> in [Imperial]:

0.250

Material:

Brass

Minimum Order:

1

Thickness >> in [Imperial]:

0.015

Approximate Diameter >> in [Imperial]:

0.200

Length >> in [Imperial]:

0.340

Material:

Brass

Minimum Order:

1

Thickness >> in [Imperial]:

0.032

Applications:

Hog Ring prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Approximate Diameter >> in [Imperial]:

0.135

Length >> in [Imperial]:

0.140

Material:

Brass|Stainless Steel

Material Diameter >> in [Imperial]:

0.055 x 0.140

Minimum Order:

1

Approximate Diameter >> in [Imperial]:

0.150

Length >> in [Imperial]:

0.340

Material:

Brass

Minimum Order:

1

Thickness >> in [Imperial]:

0.032

Approximate Diameter >> in [Imperial]:

0.140

Length >> in [Imperial]:

0.205

Material:

Brass

Minimum Order:

1

Thickness >> in [Imperial]:

0.020

Approximate Diameter >> in [Imperial]:

0.140

Length >> in [Imperial]:

0.205

Material:

Brass

Minimum Order:

1

Thickness >> in [Imperial]:

0.020

Approximate Diameter >> in [Imperial]:

0.160 x 0.060

Length >> in [Imperial]:

0.205

Material:

Brass

Minimum Order:

1

Thickness >> in [Imperial]:

0.020

Approximate Diameter >> in [Imperial]:

0.125

Length >> in [Imperial]:

0.310

Material:

Brass

Minimum Order:

1

Thickness >> in [Imperial]:

0.020

Approximate Diameter >> in [Imperial]:

0.120

Length >> in [Imperial]:

0.205

Material:

Brass

Minimum Order:

1

Thickness >> in [Imperial]:

0.020

Approximate Diameter >> in [Imperial]:

0.120

Length >> in [Imperial]:

0.205

Material:

Brass

Minimum Order:

1

Thickness >> in [Imperial]:

0.020

Applications:

Hog Ring prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Approximate Diameter >> in [Imperial]:

0.110

Length >> in [Imperial]:

0.140

Material:

Brass|Stainless Steel

Material Diameter >> in [Imperial]:

0.055 x 0.140

Minimum Order:

1

Applications:

Hog Ring prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Approximate Diameter >> in [Imperial]:

0.260

Material:

Steel

Material Diameter >> in [Imperial]:

0.114

Minimum Order:

1

Applications:

Strain reliefs thimbled aluminum clip prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Approximate Diameter >> in [Imperial]:

0.400

Material:

Aluminum

Minimum Order:

1

Thickness >> in [Imperial]:

0.055

Width >> in [Imperial]:

0.140

Applications:

Hog Ring prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Approximate Diameter >> in [Imperial]:

1.140

Material:

Steel

Material Diameter >> in [Imperial]:

0.114

Minimum Order:

1

Applications:

Strain reliefs thimbled aluminum clip prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Approximate Diameter >> in [Imperial]:

0.240

Material:

Aluminum

Minimum Order:

1

Thickness >> in [Imperial]:

0.055

Width >> in [Imperial]:

0.140

Applications:

Strain reliefs thimbled aluminum clip prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Approximate Diameter >> in [Imperial]:

0.225

Material:

Aluminum

Minimum Order:

1

Thickness >> in [Imperial]:

0.055

Width >> in [Imperial]:

0.140

Applications:

Strain reliefs thimbled aluminum clip prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Approximate Diameter >> in [Imperial]:

0.200

Material:

Aluminum

Minimum Order:

1

Thickness >> in [Imperial]:

0.055

Width >> in [Imperial]:

0.140

Applications:

Strain reliefs thimbled aluminum clip prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Approximate Diameter >> in [Imperial]:

0.180

Material:

Aluminum

Minimum Order:

1

Thickness >> in [Imperial]:

0.055

Width >> in [Imperial]:

0.140

Applications:

Strain reliefs thimbled aluminum clip prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Approximate Diameter >> in [Imperial]:

0.140

Material:

Aluminum

Minimum Order:

1

Thickness >> in [Imperial]:

0.055

Width >> in [Imperial]:

0.140

Applications:

Strain reliefs thimbled aluminum clip prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Approximate Diameter >> in [Imperial]:

0.125

Material:

Aluminum

Minimum Order:

1

Thickness >> in [Imperial]:

0.055

Width >> in [Imperial]:

0.140

Applications:

Strain reliefs thimbled aluminum clip prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Approximate Diameter >> in [Imperial]:

0.125

Material:

Aluminum

Minimum Order:

1

Thickness >> in [Imperial]:

0.055

Width >> in [Imperial]:

0.093

Applications:

Hog Ring prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Approximate Diameter >> in [Imperial]:

1.010

Material:

Steel

Material Diameter >> in [Imperial]:

0.114

Minimum Order:

1

Applications:

Hog Ring prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Approximate Diameter >> in [Imperial]:

0.260

Material:

Steel

Material Diameter >> in [Imperial]:

0.114

Minimum Order:

1

Applications:

Hog Ring prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Approximate Diameter >> in [Imperial]:

0.865

Material:

Steel

Material Diameter >> in [Imperial]:

0.114

Minimum Order:

1

Applications:

Hog Ring prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Approximate Diameter >> in [Imperial]:

0.690

Material:

Steel

Material Diameter >> in [Imperial]:

0.114

Minimum Order:

1

Applications:

Hog Ring prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Approximate Diameter >> in [Imperial]:

0.585

Material:

Steel

Material Diameter >> in [Imperial]:

0.114

Minimum Order:

1

Applications:

Hog Ring prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Approximate Diameter >> in [Imperial]:

0.530

Material:

Steel

Material Diameter >> in [Imperial]:

0.114

Minimum Order:

1

Applications:

Hog Ring prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Approximate Diameter >> in [Imperial]:

0.465

Material:

Steel

Material Diameter >> in [Imperial]:

0.114

Minimum Order:

1

Applications:

Hog Ring prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Approximate Diameter >> in [Imperial]:

0.400

Material:

Steel

Material Diameter >> in [Imperial]:

0.114

Minimum Order:

1

Applications:

Hog Ring prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Approximate Diameter >> in [Imperial]:

0.315

Material:

Steel

Material Diameter >> in [Imperial]:

0.114

Minimum Order:

1

Applications:

Hog Ring prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Approximate Diameter >> in [Imperial]:

0.315

Material:

Steel

Material Diameter >> in [Imperial]:

0.080

Minimum Order:

1

Approximate Diameter >> in [Imperial]:

0.100

Length >> in [Imperial]:

0.240

Material:

Brass

Minimum Order:

1

Thickness >> in [Imperial]:

0.020

Applications:

Strain reliefs thimbled aluminum clip prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Approximate Diameter >> in [Imperial]:

0.250 x 0.125

Material:

Aluminum

Minimum Order:

1

Thickness >> in [Imperial]:

0.055

Width >> in [Imperial]:

0.140

Applications:

Strain reliefs thimbled aluminum clip prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Approximate Diameter >> in [Imperial]:

0.400

Material:

Aluminum

Minimum Order:

1

Thickness >> in [Imperial]:

0.055

Width >> in [Imperial]:

0.140

Applications:

Strain reliefs thimbled aluminum clip prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Approximate Diameter >> in [Imperial]:

0.240

Material:

Aluminum

Minimum Order:

1

Thickness >> in [Imperial]:

0.055

Width >> in [Imperial]:

0.140

Applications:

Strain reliefs thimbled aluminum clip prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Approximate Diameter >> in [Imperial]:

0.225

Material:

Aluminum

Minimum Order:

1

Thickness >> in [Imperial]:

0.055

Width >> in [Imperial]:

0.140

Applications:

Strain reliefs thimbled aluminum clip prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Approximate Diameter >> in [Imperial]:

0.200

Material:

Aluminum

Minimum Order:

1

Thickness >> in [Imperial]:

0.055

Width >> in [Imperial]:

0.140

Applications:

Strain reliefs thimbled aluminum clip prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Approximate Diameter >> in [Imperial]:

0.180

Material:

Aluminum

Minimum Order:

1

Thickness >> in [Imperial]:

0.055

Width >> in [Imperial]:

0.140

Applications:

Strain reliefs thimbled aluminum clip prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Approximate Diameter >> in [Imperial]:

0.140

Material:

Aluminum

Minimum Order:

1

Thickness >> in [Imperial]:

0.055

Width >> in [Imperial]:

0.140

Applications:

Strain reliefs thimbled aluminum clip prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Approximate Diameter >> in [Imperial]:

0.125

Material:

Aluminum

Minimum Order:

1

Thickness >> in [Imperial]:

0.055

Width >> in [Imperial]:

0.140

Applications:

Strain reliefs thimbled aluminum clip prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Approximate Diameter >> in [Imperial]:

0.125

Material:

Aluminum

Minimum Order:

1

Thickness >> in [Imperial]:

0.055

Width >> in [Imperial]:

0.093

Applications:

Hog Ring prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Approximate Diameter >> in [Imperial]:

1.140

Material:

Steel

Material Diameter >> in [Imperial]:

0.114

Minimum Order:

1

Applications:

Hog Ring prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Approximate Diameter >> in [Imperial]:

1.010

Material:

Steel

Material Diameter >> in [Imperial]:

0.114

Minimum Order:

1

Applications:

Hog Ring prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Approximate Diameter >> in [Imperial]:

0.865

Material:

Steel

Material Diameter >> in [Imperial]:

0.114

Minimum Order:

1

Applications:

Hog Ring prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Approximate Diameter >> in [Imperial]:

0.690

Material:

Steel

Material Diameter >> in [Imperial]:

0.114

Minimum Order:

1

Applications:

Hog Ring prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Approximate Diameter >> in [Imperial]:

0.585

Material:

Steel

Material Diameter >> in [Imperial]:

0.114

Minimum Order:

1

Applications:

Hog Ring prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Approximate Diameter >> in [Imperial]:

0.530

Material:

Steel

Material Diameter >> in [Imperial]:

0.114

Minimum Order:

1

Applications:

Hog Ring prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Approximate Diameter >> in [Imperial]:

0.465

Material:

Steel

Material Diameter >> in [Imperial]:

0.114

Minimum Order:

1

Applications:

Hog Ring prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Approximate Diameter >> in [Imperial]:

0.400

Material:

Steel

Material Diameter >> in [Imperial]:

0.114

Minimum Order:

1

Applications:

Hog Ring prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Approximate Diameter >> in [Imperial]:

0.315

Material:

Steel

Material Diameter >> in [Imperial]:

0.114

Minimum Order:

1

Applications:

Hog Ring prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Approximate Diameter >> in [Imperial]:

0.315

Material:

Steel

Material Diameter >> in [Imperial]:

0.080

Minimum Order:

1

Applications:

Hog Ring prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Approximate Diameter >> in [Imperial]:

0.260

Material:

Steel

Material Diameter >> in [Imperial]:

0.114

Minimum Order:

1

Applications:

Hog Ring prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Approximate Diameter >> in [Imperial]:

0.260

Material:

Steel

Material Diameter >> in [Imperial]:

0.114

Minimum Order:

1

Applications:

Hog Ring prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Approximate Diameter >> in [Imperial]:

0.135

Length >> in [Imperial]:

0.140

Material:

Brass|Stainless Steel

Material Diameter >> in [Imperial]:

0.055 x 0.140

Minimum Order:

1

Applications:

Hog Ring prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Approximate Diameter >> in [Imperial]:

0.110

Length >> in [Imperial]:

0.140

Material:

Brass|Stainless Steel

Material Diameter >> in [Imperial]:

0.055 x 0.140

Minimum Order:

1

Applications:

Hog Ring prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Approximate Diameter >> in [Imperial]:

0.100

Material:

Steel

Material Diameter >> in [Imperial]:

0.060

Minimum Order:

1

Approximate Diameter >> in [Imperial]:

0.437

Length >> in [Imperial]:

0.360

Material:

Brass

Minimum Order:

1

Thickness >> in [Imperial]:

0.040

Approximate Diameter >> in [Imperial]:

0.375

Length >> in [Imperial]:

0.360

Material:

Brass

Minimum Order:

1

Thickness >> in [Imperial]:

0.040

Approximate Diameter >> in [Imperial]:

0.250

Length >> in [Imperial]:

0.220

Material:

Brass|Steel

Minimum Order:

1

Thickness >> in [Imperial]:

0.032

Approximate Diameter >> in [Imperial]:

0.200

Length >> in [Imperial]:

0.281

Material:

Steel

Minimum Order:

1

Thickness >> in [Imperial]:

0.032

Approximate Diameter >> in [Imperial]:

0.190

Length >> in [Imperial]:

0.281

Material:

Steel

Minimum Order:

1

Thickness >> in [Imperial]:

0.050

Approximate Diameter >> in [Imperial]:

0.200 x 0.100

Length >> in [Imperial]:

0.250

Material:

Brass

Minimum Order:

1

Thickness >> in [Imperial]:

0.015

Approximate Diameter >> in [Imperial]:

0.170 x 0.080

Length >> in [Imperial]:

0.340

Material:

Brass

Minimum Order:

1

Thickness >> in [Imperial]:

0.032

Approximate Diameter >> in [Imperial]:

0.200

Length >> in [Imperial]:

0.340

Material:

Brass

Minimum Order:

1

Thickness >> in [Imperial]:

0.032

Approximate Diameter >> in [Imperial]:

0.150

Length >> in [Imperial]:

0.340

Material:

Brass

Minimum Order:

1

Thickness >> in [Imperial]:

0.032

Approximate Diameter >> in [Imperial]:

0.140

Length >> in [Imperial]:

0.205

Material:

Brass

Minimum Order:

1

Thickness >> in [Imperial]:

0.020

Approximate Diameter >> in [Imperial]:

0.140

Length >> in [Imperial]:

0.205

Material:

Brass

Minimum Order:

1

Thickness >> in [Imperial]:

0.020

Approximate Diameter >> in [Imperial]:

0.160 x 0.060

Length >> in [Imperial]:

0.205

Material:

Brass

Minimum Order:

1

Thickness >> in [Imperial]:

0.020

Approximate Diameter >> in [Imperial]:

0.125

Length >> in [Imperial]:

0.310

Material:

Brass

Minimum Order:

1

Thickness >> in [Imperial]:

0.020

Approximate Diameter >> in [Imperial]:

0.120

Length >> in [Imperial]:

0.205

Material:

Brass

Minimum Order:

1

Thickness >> in [Imperial]:

0.020

Approximate Diameter >> in [Imperial]:

0.120

Length >> in [Imperial]:

0.205

Material:

Brass

Minimum Order:

1

Thickness >> in [Imperial]:

0.020

Approximate Diameter >> in [Imperial]:

0.100

Length >> in [Imperial]:

0.240

Material:

Brass

Minimum Order:

1

Thickness >> in [Imperial]:

0.020

Strain Reliefs

Made in the U.S.A. since 1946. An ISO9001 Certified Manufacturer of Metal Stampings including Thimbled Aluminum Clip Strain Reliefs.

The special embossed pattern rolled into the surface of these Aluminum Clips gives them superior gripping power in a lightweight application. These Thimbled Aluminum Clips are applied to electrical cord, electronic cable, and industrial wire to prevent pullout, to mold over, to anchor assemblies & to join cables together. These Thimbled Aluminum Clips can accommodate cord, cable and wire diameters from 0.125” to 0.400”. Available Options From: In Stock Inventory, In House Tooling for Production Runs, Samples Applied for Prototyping, New Tooling to Produce Your Custom Part Requirements and Custom Application Equipment to meet your Job Specifications.

Thimbled Aluminum Clips are used as; Automotive Parts, Band Clamps, Cable Clamps, Clasps, Clips, Lug Connections, Connectors, Electric Connectors, Electric Wire & Cable Connectors, Wire Connectors, Cordage Crimps, Electronic Hardware, Fasteners, Automotive Fasteners, Strain Relief Grips, Cable & Wire Lugs, Electrical Lugs, Cable Splices, Metal Stampings, Strain Reliefs.

The special embossed pattern rolled into the surface of these Aluminum Clips gives them superior gripping power in a lightweight application. These Thimbled Aluminum Clips are applied to electrical cord, electronic cable, and industrial wire to prevent pullout, to mold over, to anchor assemblies & to join cables together. These Thimbled Aluminum Clips can accommodate cord, cable and wire diameters from 0.125” to 0.400”. Available Options From: In Stock Inventory, In House Tooling for Production Runs, Samples Applied for Prototyping, New Tooling to Produce Your Custom Part Requirements and Custom Application Equipment to meet your Job Specifications.

Thimbled Aluminum Clips are used as; Automotive Parts, Band Clamps, Cable Clamps, Clasps, Clips, Lug Connections, Connectors, Electric Connectors, Electric Wire & Cable Connectors, Wire Connectors, Cordage Crimps, Electronic Hardware, Fasteners, Automotive Fasteners, Strain Relief Grips, Cable & Wire Lugs, Electrical Lugs, Cable Splices, Metal Stampings, Strain Reliefs.

Applications:

Strain reliefs thimbled aluminum clip prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Molding a plug body onto a cable with a crimped strain reliefs thimbled aluminum clip prevents pull-out of the cable.

Strain reliefs thimbled aluminum clip crimped onto wire

Approximate Diameter >> in [Imperial]:

0.250 x 0.125

Material:

Aluminum

Minimum Order:

1

Thickness >> in [Imperial]:

0.055

Width >> in [Imperial]:

0.140

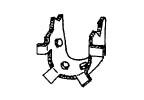

Made in the U.S.A. since 1946. An ISO9001 Certified Manufacturer of Metal Stampings including Ear Band Strain Reliefs.

These specially designed Ear Band Strain Reliefs are manufactured from Brass and Steel. The Ear Band is a “U” Shaped Crimp with Ears located on the Top of the Crimp. The Ear Bands can be used on electrical cord, poly cord, electronic cable & wire to increase the cord diameter, to mold over, prevent pull thru, and to anchor assemblies. These Ear Band Strain Reliefs can accommodate cord, cable and wire diameters from 0.100” to 0.437”. Available Options From: In Stock Inventory, In House Tooling for Production Runs, Samples Applied for Prototyping, New Tooling to Produce Your Custom Part Requirements and Custom Application Equipment to meet your Job Specifications.

Ear Band Strain Reliefs are used as; Automotive Parts, Band Clamps, Cable Clamps, Clasps, Clips, Crimps, Bungee Cord Crimps, Poly Cord Crimps, Lug Connections, Connectors, Electric Connectors, Electric Wire & Cable Connectors, Wire Connectors, Cordage Crimps, Electronic Hardware, Fasteners, Automotive Fasteners, Strain Relief Grips, Lanyard Hooks, Cable & Wire Lugs, Electrical Lugs, Cable Splices, Metal Stampings, Strain Reliefs, Webbing Fastener.

These specially designed Ear Band Strain Reliefs are manufactured from Brass and Steel. The Ear Band is a “U” Shaped Crimp with Ears located on the Top of the Crimp. The Ear Bands can be used on electrical cord, poly cord, electronic cable & wire to increase the cord diameter, to mold over, prevent pull thru, and to anchor assemblies. These Ear Band Strain Reliefs can accommodate cord, cable and wire diameters from 0.100” to 0.437”. Available Options From: In Stock Inventory, In House Tooling for Production Runs, Samples Applied for Prototyping, New Tooling to Produce Your Custom Part Requirements and Custom Application Equipment to meet your Job Specifications.

Ear Band Strain Reliefs are used as; Automotive Parts, Band Clamps, Cable Clamps, Clasps, Clips, Crimps, Bungee Cord Crimps, Poly Cord Crimps, Lug Connections, Connectors, Electric Connectors, Electric Wire & Cable Connectors, Wire Connectors, Cordage Crimps, Electronic Hardware, Fasteners, Automotive Fasteners, Strain Relief Grips, Lanyard Hooks, Cable & Wire Lugs, Electrical Lugs, Cable Splices, Metal Stampings, Strain Reliefs, Webbing Fastener.

Approximate Diameter >> in [Imperial]:

0.170 x 0.080

Length >> in [Imperial]:

0.340

Material:

Brass

Minimum Order:

1

Thickness >> in [Imperial]:

0.032

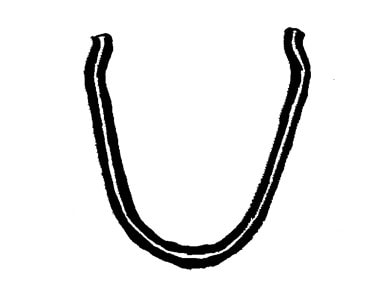

Made in the U.S.A. since 1946. An ISO9001 Certified Manufacturer of Metal Stampings including Steel Hog Ring Strain Reliefs.

These steel hog rings are applied to electrical cord, electronic cable, and industrial wire to prevent pullout, to mold over, to anchor assemblies & to join cables together. These Hog Rings can accommodate cord, cable and wire diameters from 0.100” to 1.140”. Available Options From: In Stock Inventory, In House Tooling for Production Runs, Samples Applied for Prototyping, New Tooling to Produce Your Custom Part Requirements and Custom Application Equipment to meet your Job Specifications.

Hog Rings are used as; Automotive Parts, Band Clamps, Cable Clamps, Clasps, Clips, Lug Connections, Connectors, Electric Connectors, Electric Wire & Cable Connectors, Wire Connectors, Cordage Crimps, Electronic Hardware, Fasteners, Automotive Fasteners, Strain Relief Grips, Cable & Wire Lugs, Electrical Lugs, Cable Splices, Metal Stampings, Strain Reliefs.

These steel hog rings are applied to electrical cord, electronic cable, and industrial wire to prevent pullout, to mold over, to anchor assemblies & to join cables together. These Hog Rings can accommodate cord, cable and wire diameters from 0.100” to 1.140”. Available Options From: In Stock Inventory, In House Tooling for Production Runs, Samples Applied for Prototyping, New Tooling to Produce Your Custom Part Requirements and Custom Application Equipment to meet your Job Specifications.

Hog Rings are used as; Automotive Parts, Band Clamps, Cable Clamps, Clasps, Clips, Lug Connections, Connectors, Electric Connectors, Electric Wire & Cable Connectors, Wire Connectors, Cordage Crimps, Electronic Hardware, Fasteners, Automotive Fasteners, Strain Relief Grips, Cable & Wire Lugs, Electrical Lugs, Cable Splices, Metal Stampings, Strain Reliefs.

Applications:

Hog Ring prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Approximate Diameter >> in [Imperial]:

0.100

Material:

Steel

Material Diameter >> in [Imperial]:

0.060

Minimum Order:

1

Made in the U.S.A. since 1946. An ISO9001 Certified Manufacturer of Metal Stampings including Ear Band Strain Reliefs.

These specially designed Ear Band Strain Reliefs are manufactured from Brass and Steel. The Ear Band is a “U” Shaped Crimp with Ears located on the Top of the Crimp. The Ear Bands can be used on electrical cord, poly cord, electronic cable & wire to increase the cord diameter, to mold over, prevent pull thru, and to anchor assemblies. These Ear Band Strain Reliefs can accommodate cord, cable and wire diameters from 0.100” to 0.437”. Available Options From: In Stock Inventory, In House Tooling for Production Runs, Samples Applied for Prototyping, New Tooling to Produce Your Custom Part Requirements and Custom Application Equipment to meet your Job Specifications.

Ear Band Strain Reliefs are used as; Automotive Parts, Band Clamps, Cable Clamps, Clasps, Clips, Crimps, Bungee Cord Crimps, Poly Cord Crimps, Lug Connections, Connectors, Electric Connectors, Electric Wire & Cable Connectors, Wire Connectors, Cordage Crimps, Electronic Hardware, Fasteners, Automotive Fasteners, Strain Relief Grips, Lanyard Hooks, Cable & Wire Lugs, Electrical Lugs, Cable Splices, Metal Stampings, Strain Reliefs, Webbing Fastener.

These specially designed Ear Band Strain Reliefs are manufactured from Brass and Steel. The Ear Band is a “U” Shaped Crimp with Ears located on the Top of the Crimp. The Ear Bands can be used on electrical cord, poly cord, electronic cable & wire to increase the cord diameter, to mold over, prevent pull thru, and to anchor assemblies. These Ear Band Strain Reliefs can accommodate cord, cable and wire diameters from 0.100” to 0.437”. Available Options From: In Stock Inventory, In House Tooling for Production Runs, Samples Applied for Prototyping, New Tooling to Produce Your Custom Part Requirements and Custom Application Equipment to meet your Job Specifications.

Ear Band Strain Reliefs are used as; Automotive Parts, Band Clamps, Cable Clamps, Clasps, Clips, Crimps, Bungee Cord Crimps, Poly Cord Crimps, Lug Connections, Connectors, Electric Connectors, Electric Wire & Cable Connectors, Wire Connectors, Cordage Crimps, Electronic Hardware, Fasteners, Automotive Fasteners, Strain Relief Grips, Lanyard Hooks, Cable & Wire Lugs, Electrical Lugs, Cable Splices, Metal Stampings, Strain Reliefs, Webbing Fastener.

Approximate Diameter >> in [Imperial]:

0.437

Length >> in [Imperial]:

0.360

Material:

Brass

Minimum Order:

1

Thickness >> in [Imperial]:

0.040

Made in the U.S.A. since 1946. An ISO9001 Certified Manufacturer of Metal Stampings including Ear Band Strain Reliefs.

These specially designed Ear Band Strain Reliefs are manufactured from Brass and Steel. The Ear Band is a “U” Shaped Crimp with Ears located on the Top of the Crimp. The Ear Bands can be used on electrical cord, poly cord, electronic cable & wire to increase the cord diameter, to mold over, prevent pull thru, and to anchor assemblies. These Ear Band Strain Reliefs can accommodate cord, cable and wire diameters from 0.100” to 0.437”. Available Options From: In Stock Inventory, In House Tooling for Production Runs, Samples Applied for Prototyping, New Tooling to Produce Your Custom Part Requirements and Custom Application Equipment to meet your Job Specifications.

Ear Band Strain Reliefs are used as; Automotive Parts, Band Clamps, Cable Clamps, Clasps, Clips, Crimps, Bungee Cord Crimps, Poly Cord Crimps, Lug Connections, Connectors, Electric Connectors, Electric Wire & Cable Connectors, Wire Connectors, Cordage Crimps, Electronic Hardware, Fasteners, Automotive Fasteners, Strain Relief Grips, Lanyard Hooks, Cable & Wire Lugs, Electrical Lugs, Cable Splices, Metal Stampings, Strain Reliefs, Webbing Fastener.

These specially designed Ear Band Strain Reliefs are manufactured from Brass and Steel. The Ear Band is a “U” Shaped Crimp with Ears located on the Top of the Crimp. The Ear Bands can be used on electrical cord, poly cord, electronic cable & wire to increase the cord diameter, to mold over, prevent pull thru, and to anchor assemblies. These Ear Band Strain Reliefs can accommodate cord, cable and wire diameters from 0.100” to 0.437”. Available Options From: In Stock Inventory, In House Tooling for Production Runs, Samples Applied for Prototyping, New Tooling to Produce Your Custom Part Requirements and Custom Application Equipment to meet your Job Specifications.

Ear Band Strain Reliefs are used as; Automotive Parts, Band Clamps, Cable Clamps, Clasps, Clips, Crimps, Bungee Cord Crimps, Poly Cord Crimps, Lug Connections, Connectors, Electric Connectors, Electric Wire & Cable Connectors, Wire Connectors, Cordage Crimps, Electronic Hardware, Fasteners, Automotive Fasteners, Strain Relief Grips, Lanyard Hooks, Cable & Wire Lugs, Electrical Lugs, Cable Splices, Metal Stampings, Strain Reliefs, Webbing Fastener.

Approximate Diameter >> in [Imperial]:

0.375

Length >> in [Imperial]:

0.360

Material:

Brass

Minimum Order:

1

Thickness >> in [Imperial]:

0.040

Made in the U.S.A. since 1946. An ISO9001 Certified Manufacturer of Metal Stampings including Ear Band Strain Reliefs.

These specially designed Ear Band Strain Reliefs are manufactured from Brass and Steel. The Ear Band is a “U” Shaped Crimp with Ears located on the Top of the Crimp. The Ear Bands can be used on electrical cord, poly cord, electronic cable & wire to increase the cord diameter, to mold over, prevent pull thru, and to anchor assemblies. These Ear Band Strain Reliefs can accommodate cord, cable and wire diameters from 0.100” to 0.437”. Available Options From: In Stock Inventory, In House Tooling for Production Runs, Samples Applied for Prototyping, New Tooling to Produce Your Custom Part Requirements and Custom Application Equipment to meet your Job Specifications.

Ear Band Strain Reliefs are used as; Automotive Parts, Band Clamps, Cable Clamps, Clasps, Clips, Crimps, Bungee Cord Crimps, Poly Cord Crimps, Lug Connections, Connectors, Electric Connectors, Electric Wire & Cable Connectors, Wire Connectors, Cordage Crimps, Electronic Hardware, Fasteners, Automotive Fasteners, Strain Relief Grips, Lanyard Hooks, Cable & Wire Lugs, Electrical Lugs, Cable Splices, Metal Stampings, Strain Reliefs, Webbing Fastener.

These specially designed Ear Band Strain Reliefs are manufactured from Brass and Steel. The Ear Band is a “U” Shaped Crimp with Ears located on the Top of the Crimp. The Ear Bands can be used on electrical cord, poly cord, electronic cable & wire to increase the cord diameter, to mold over, prevent pull thru, and to anchor assemblies. These Ear Band Strain Reliefs can accommodate cord, cable and wire diameters from 0.100” to 0.437”. Available Options From: In Stock Inventory, In House Tooling for Production Runs, Samples Applied for Prototyping, New Tooling to Produce Your Custom Part Requirements and Custom Application Equipment to meet your Job Specifications.

Ear Band Strain Reliefs are used as; Automotive Parts, Band Clamps, Cable Clamps, Clasps, Clips, Crimps, Bungee Cord Crimps, Poly Cord Crimps, Lug Connections, Connectors, Electric Connectors, Electric Wire & Cable Connectors, Wire Connectors, Cordage Crimps, Electronic Hardware, Fasteners, Automotive Fasteners, Strain Relief Grips, Lanyard Hooks, Cable & Wire Lugs, Electrical Lugs, Cable Splices, Metal Stampings, Strain Reliefs, Webbing Fastener.

Approximate Diameter >> in [Imperial]:

0.250

Length >> in [Imperial]:

0.220

Material:

Brass|Steel

Minimum Order:

1

Thickness >> in [Imperial]:

0.032

Made in the U.S.A. since 1946. An ISO9001 Certified Manufacturer of Metal Stampings including Ear Band Strain Reliefs.

These specially designed Ear Band Strain Reliefs are manufactured from Brass and Steel. The Ear Band is a “U” Shaped Crimp with Ears located on the Top of the Crimp. The Ear Bands can be used on electrical cord, poly cord, electronic cable & wire to increase the cord diameter, to mold over, prevent pull thru, and to anchor assemblies. These Ear Band Strain Reliefs can accommodate cord, cable and wire diameters from 0.100” to 0.437”. Available Options From: In Stock Inventory, In House Tooling for Production Runs, Samples Applied for Prototyping, New Tooling to Produce Your Custom Part Requirements and Custom Application Equipment to meet your Job Specifications.

Ear Band Strain Reliefs are used as; Automotive Parts, Band Clamps, Cable Clamps, Clasps, Clips, Crimps, Bungee Cord Crimps, Poly Cord Crimps, Lug Connections, Connectors, Electric Connectors, Electric Wire & Cable Connectors, Wire Connectors, Cordage Crimps, Electronic Hardware, Fasteners, Automotive Fasteners, Strain Relief Grips, Lanyard Hooks, Cable & Wire Lugs, Electrical Lugs, Cable Splices, Metal Stampings, Strain Reliefs, Webbing Fastener.

These specially designed Ear Band Strain Reliefs are manufactured from Brass and Steel. The Ear Band is a “U” Shaped Crimp with Ears located on the Top of the Crimp. The Ear Bands can be used on electrical cord, poly cord, electronic cable & wire to increase the cord diameter, to mold over, prevent pull thru, and to anchor assemblies. These Ear Band Strain Reliefs can accommodate cord, cable and wire diameters from 0.100” to 0.437”. Available Options From: In Stock Inventory, In House Tooling for Production Runs, Samples Applied for Prototyping, New Tooling to Produce Your Custom Part Requirements and Custom Application Equipment to meet your Job Specifications.

Ear Band Strain Reliefs are used as; Automotive Parts, Band Clamps, Cable Clamps, Clasps, Clips, Crimps, Bungee Cord Crimps, Poly Cord Crimps, Lug Connections, Connectors, Electric Connectors, Electric Wire & Cable Connectors, Wire Connectors, Cordage Crimps, Electronic Hardware, Fasteners, Automotive Fasteners, Strain Relief Grips, Lanyard Hooks, Cable & Wire Lugs, Electrical Lugs, Cable Splices, Metal Stampings, Strain Reliefs, Webbing Fastener.

Approximate Diameter >> in [Imperial]:

0.200

Length >> in [Imperial]:

0.281

Material:

Steel

Minimum Order:

1

Thickness >> in [Imperial]:

0.032

Made in the U.S.A. since 1946. An ISO9001 Certified Manufacturer of Metal Stampings including Ear Band Strain Reliefs.

These specially designed Ear Band Strain Reliefs are manufactured from Brass and Steel. The Ear Band is a “U” Shaped Crimp with Ears located on the Top of the Crimp. The Ear Bands can be used on electrical cord, poly cord, electronic cable & wire to increase the cord diameter, to mold over, prevent pull thru, and to anchor assemblies. These Ear Band Strain Reliefs can accommodate cord, cable and wire diameters from 0.100” to 0.437”. Available Options From: In Stock Inventory, In House Tooling for Production Runs, Samples Applied for Prototyping, New Tooling to Produce Your Custom Part Requirements and Custom Application Equipment to meet your Job Specifications.

Ear Band Strain Reliefs are used as; Automotive Parts, Band Clamps, Cable Clamps, Clasps, Clips, Crimps, Bungee Cord Crimps, Poly Cord Crimps, Lug Connections, Connectors, Electric Connectors, Electric Wire & Cable Connectors, Wire Connectors, Cordage Crimps, Electronic Hardware, Fasteners, Automotive Fasteners, Strain Relief Grips, Lanyard Hooks, Cable & Wire Lugs, Electrical Lugs, Cable Splices, Metal Stampings, Strain Reliefs, Webbing Fastener.

These specially designed Ear Band Strain Reliefs are manufactured from Brass and Steel. The Ear Band is a “U” Shaped Crimp with Ears located on the Top of the Crimp. The Ear Bands can be used on electrical cord, poly cord, electronic cable & wire to increase the cord diameter, to mold over, prevent pull thru, and to anchor assemblies. These Ear Band Strain Reliefs can accommodate cord, cable and wire diameters from 0.100” to 0.437”. Available Options From: In Stock Inventory, In House Tooling for Production Runs, Samples Applied for Prototyping, New Tooling to Produce Your Custom Part Requirements and Custom Application Equipment to meet your Job Specifications.

Ear Band Strain Reliefs are used as; Automotive Parts, Band Clamps, Cable Clamps, Clasps, Clips, Crimps, Bungee Cord Crimps, Poly Cord Crimps, Lug Connections, Connectors, Electric Connectors, Electric Wire & Cable Connectors, Wire Connectors, Cordage Crimps, Electronic Hardware, Fasteners, Automotive Fasteners, Strain Relief Grips, Lanyard Hooks, Cable & Wire Lugs, Electrical Lugs, Cable Splices, Metal Stampings, Strain Reliefs, Webbing Fastener.

Approximate Diameter >> in [Imperial]:

0.190

Length >> in [Imperial]:

0.281

Material:

Steel

Minimum Order:

1

Thickness >> in [Imperial]:

0.050

Made in the U.S.A. since 1946. An ISO9001 Certified Manufacturer of Metal Stampings including Ear Band Strain Reliefs.

These specially designed Ear Band Strain Reliefs are manufactured from Brass and Steel. The Ear Band is a “U” Shaped Crimp with Ears located on the Top of the Crimp. The Ear Bands can be used on electrical cord, poly cord, electronic cable & wire to increase the cord diameter, to mold over, prevent pull thru, and to anchor assemblies. These Ear Band Strain Reliefs can accommodate cord, cable and wire diameters from 0.100” to 0.437”. Available Options From: In Stock Inventory, In House Tooling for Production Runs, Samples Applied for Prototyping, New Tooling to Produce Your Custom Part Requirements and Custom Application Equipment to meet your Job Specifications.

Ear Band Strain Reliefs are used as; Automotive Parts, Band Clamps, Cable Clamps, Clasps, Clips, Crimps, Bungee Cord Crimps, Poly Cord Crimps, Lug Connections, Connectors, Electric Connectors, Electric Wire & Cable Connectors, Wire Connectors, Cordage Crimps, Electronic Hardware, Fasteners, Automotive Fasteners, Strain Relief Grips, Lanyard Hooks, Cable & Wire Lugs, Electrical Lugs, Cable Splices, Metal Stampings, Strain Reliefs, Webbing Fastener.

These specially designed Ear Band Strain Reliefs are manufactured from Brass and Steel. The Ear Band is a “U” Shaped Crimp with Ears located on the Top of the Crimp. The Ear Bands can be used on electrical cord, poly cord, electronic cable & wire to increase the cord diameter, to mold over, prevent pull thru, and to anchor assemblies. These Ear Band Strain Reliefs can accommodate cord, cable and wire diameters from 0.100” to 0.437”. Available Options From: In Stock Inventory, In House Tooling for Production Runs, Samples Applied for Prototyping, New Tooling to Produce Your Custom Part Requirements and Custom Application Equipment to meet your Job Specifications.

Ear Band Strain Reliefs are used as; Automotive Parts, Band Clamps, Cable Clamps, Clasps, Clips, Crimps, Bungee Cord Crimps, Poly Cord Crimps, Lug Connections, Connectors, Electric Connectors, Electric Wire & Cable Connectors, Wire Connectors, Cordage Crimps, Electronic Hardware, Fasteners, Automotive Fasteners, Strain Relief Grips, Lanyard Hooks, Cable & Wire Lugs, Electrical Lugs, Cable Splices, Metal Stampings, Strain Reliefs, Webbing Fastener.

Approximate Diameter >> in [Imperial]:

0.200 x 0.100

Length >> in [Imperial]:

0.250

Material:

Brass

Minimum Order:

1

Thickness >> in [Imperial]:

0.015

Made in the U.S.A. since 1946. An ISO9001 Certified Manufacturer of Metal Stampings including Ear Band Strain Reliefs.

These specially designed Ear Band Strain Reliefs are manufactured from Brass and Steel. The Ear Band is a “U” Shaped Crimp with Ears located on the Top of the Crimp. The Ear Bands can be used on electrical cord, poly cord, electronic cable & wire to increase the cord diameter, to mold over, prevent pull thru, and to anchor assemblies. These Ear Band Strain Reliefs can accommodate cord, cable and wire diameters from 0.100” to 0.437”. Available Options From: In Stock Inventory, In House Tooling for Production Runs, Samples Applied for Prototyping, New Tooling to Produce Your Custom Part Requirements and Custom Application Equipment to meet your Job Specifications.

Ear Band Strain Reliefs are used as; Automotive Parts, Band Clamps, Cable Clamps, Clasps, Clips, Crimps, Bungee Cord Crimps, Poly Cord Crimps, Lug Connections, Connectors, Electric Connectors, Electric Wire & Cable Connectors, Wire Connectors, Cordage Crimps, Electronic Hardware, Fasteners, Automotive Fasteners, Strain Relief Grips, Lanyard Hooks, Cable & Wire Lugs, Electrical Lugs, Cable Splices, Metal Stampings, Strain Reliefs, Webbing Fastener.

These specially designed Ear Band Strain Reliefs are manufactured from Brass and Steel. The Ear Band is a “U” Shaped Crimp with Ears located on the Top of the Crimp. The Ear Bands can be used on electrical cord, poly cord, electronic cable & wire to increase the cord diameter, to mold over, prevent pull thru, and to anchor assemblies. These Ear Band Strain Reliefs can accommodate cord, cable and wire diameters from 0.100” to 0.437”. Available Options From: In Stock Inventory, In House Tooling for Production Runs, Samples Applied for Prototyping, New Tooling to Produce Your Custom Part Requirements and Custom Application Equipment to meet your Job Specifications.

Ear Band Strain Reliefs are used as; Automotive Parts, Band Clamps, Cable Clamps, Clasps, Clips, Crimps, Bungee Cord Crimps, Poly Cord Crimps, Lug Connections, Connectors, Electric Connectors, Electric Wire & Cable Connectors, Wire Connectors, Cordage Crimps, Electronic Hardware, Fasteners, Automotive Fasteners, Strain Relief Grips, Lanyard Hooks, Cable & Wire Lugs, Electrical Lugs, Cable Splices, Metal Stampings, Strain Reliefs, Webbing Fastener.

Approximate Diameter >> in [Imperial]:

0.200

Length >> in [Imperial]:

0.340

Material:

Brass

Minimum Order:

1

Thickness >> in [Imperial]:

0.032

Made in the U.S.A. since 1946. An ISO9001 Certified Manufacturer of Metal Stampings including Steel Hog Ring Strain Reliefs.

These steel hog rings are applied to electrical cord, electronic cable, and industrial wire to prevent pullout, to mold over, to anchor assemblies & to join cables together. These Hog Rings can accommodate cord, cable and wire diameters from 0.100” to 1.140”. Available Options From: In Stock Inventory, In House Tooling for Production Runs, Samples Applied for Prototyping, New Tooling to Produce Your Custom Part Requirements and Custom Application Equipment to meet your Job Specifications.

Hog Rings are used as; Automotive Parts, Band Clamps, Cable Clamps, Clasps, Clips, Lug Connections, Connectors, Electric Connectors, Electric Wire & Cable Connectors, Wire Connectors, Cordage Crimps, Electronic Hardware, Fasteners, Automotive Fasteners, Strain Relief Grips, Cable & Wire Lugs, Electrical Lugs, Cable Splices, Metal Stampings, Strain Reliefs.

These steel hog rings are applied to electrical cord, electronic cable, and industrial wire to prevent pullout, to mold over, to anchor assemblies & to join cables together. These Hog Rings can accommodate cord, cable and wire diameters from 0.100” to 1.140”. Available Options From: In Stock Inventory, In House Tooling for Production Runs, Samples Applied for Prototyping, New Tooling to Produce Your Custom Part Requirements and Custom Application Equipment to meet your Job Specifications.

Hog Rings are used as; Automotive Parts, Band Clamps, Cable Clamps, Clasps, Clips, Lug Connections, Connectors, Electric Connectors, Electric Wire & Cable Connectors, Wire Connectors, Cordage Crimps, Electronic Hardware, Fasteners, Automotive Fasteners, Strain Relief Grips, Cable & Wire Lugs, Electrical Lugs, Cable Splices, Metal Stampings, Strain Reliefs.

Applications:

Hog Ring prevents wire pull-out through hole.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Molding a plug body onto a cable with a crimped hog ring prevents pull-out of the cable.

Hog Ring crimped onto wire fits into nest in case and prevents pull-out.

Approximate Diameter >> in [Imperial]:

0.135

Length >> in [Imperial]:

0.140

Material:

Brass|Stainless Steel

Material Diameter >> in [Imperial]:

0.055 x 0.140

Minimum Order:

1

Made in the U.S.A. since 1946. An ISO9001 Certified Manufacturer of Metal Stampings including Ear Band Strain Reliefs.

These specially designed Ear Band Strain Reliefs are manufactured from Brass and Steel. The Ear Band is a “U” Shaped Crimp with Ears located on the Top of the Crimp. The Ear Bands can be used on electrical cord, poly cord, electronic cable & wire to increase the cord diameter, to mold over, prevent pull thru, and to anchor assemblies. These Ear Band Strain Reliefs can accommodate cord, cable and wire diameters from 0.100” to 0.437”. Available Options From: In Stock Inventory, In House Tooling for Production Runs, Samples Applied for Prototyping, New Tooling to Produce Your Custom Part Requirements and Custom Application Equipment to meet your Job Specifications.

Ear Band Strain Reliefs are used as; Automotive Parts, Band Clamps, Cable Clamps, Clasps, Clips, Crimps, Bungee Cord Crimps, Poly Cord Crimps, Lug Connections, Connectors, Electric Connectors, Electric Wire & Cable Connectors, Wire Connectors, Cordage Crimps, Electronic Hardware, Fasteners, Automotive Fasteners, Strain Relief Grips, Lanyard Hooks, Cable & Wire Lugs, Electrical Lugs, Cable Splices, Metal Stampings, Strain Reliefs, Webbing Fastener.

These specially designed Ear Band Strain Reliefs are manufactured from Brass and Steel. The Ear Band is a “U” Shaped Crimp with Ears located on the Top of the Crimp. The Ear Bands can be used on electrical cord, poly cord, electronic cable & wire to increase the cord diameter, to mold over, prevent pull thru, and to anchor assemblies. These Ear Band Strain Reliefs can accommodate cord, cable and wire diameters from 0.100” to 0.437”. Available Options From: In Stock Inventory, In House Tooling for Production Runs, Samples Applied for Prototyping, New Tooling to Produce Your Custom Part Requirements and Custom Application Equipment to meet your Job Specifications.

Ear Band Strain Reliefs are used as; Automotive Parts, Band Clamps, Cable Clamps, Clasps, Clips, Crimps, Bungee Cord Crimps, Poly Cord Crimps, Lug Connections, Connectors, Electric Connectors, Electric Wire & Cable Connectors, Wire Connectors, Cordage Crimps, Electronic Hardware, Fasteners, Automotive Fasteners, Strain Relief Grips, Lanyard Hooks, Cable & Wire Lugs, Electrical Lugs, Cable Splices, Metal Stampings, Strain Reliefs, Webbing Fastener.

Approximate Diameter >> in [Imperial]:

0.150

Length >> in [Imperial]:

0.340

Material:

Brass

Minimum Order:

1

Thickness >> in [Imperial]:

0.032

Made in the U.S.A. since 1946. An ISO9001 Certified Manufacturer of Metal Stampings including Ear Band Strain Reliefs.

These specially designed Ear Band Strain Reliefs are manufactured from Brass and Steel. The Ear Band is a “U” Shaped Crimp with Ears located on the Top of the Crimp. The Ear Bands can be used on electrical cord, poly cord, electronic cable & wire to increase the cord diameter, to mold over, prevent pull thru, and to anchor assemblies. These Ear Band Strain Reliefs can accommodate cord, cable and wire diameters from 0.100” to 0.437”. Available Options From: In Stock Inventory, In House Tooling for Production Runs, Samples Applied for Prototyping, New Tooling to Produce Your Custom Part Requirements and Custom Application Equipment to meet your Job Specifications.

Ear Band Strain Reliefs are used as; Automotive Parts, Band Clamps, Cable Clamps, Clasps, Clips, Crimps, Bungee Cord Crimps, Poly Cord Crimps, Lug Connections, Connectors, Electric Connectors, Electric Wire & Cable Connectors, Wire Connectors, Cordage Crimps, Electronic Hardware, Fasteners, Automotive Fasteners, Strain Relief Grips, Lanyard Hooks, Cable & Wire Lugs, Electrical Lugs, Cable Splices, Metal Stampings, Strain Reliefs, Webbing Fastener.

These specially designed Ear Band Strain Reliefs are manufactured from Brass and Steel. The Ear Band is a “U” Shaped Crimp with Ears located on the Top of the Crimp. The Ear Bands can be used on electrical cord, poly cord, electronic cable & wire to increase the cord diameter, to mold over, prevent pull thru, and to anchor assemblies. These Ear Band Strain Reliefs can accommodate cord, cable and wire diameters from 0.100” to 0.437”. Available Options From: In Stock Inventory, In House Tooling for Production Runs, Samples Applied for Prototyping, New Tooling to Produce Your Custom Part Requirements and Custom Application Equipment to meet your Job Specifications.

Ear Band Strain Reliefs are used as; Automotive Parts, Band Clamps, Cable Clamps, Clasps, Clips, Crimps, Bungee Cord Crimps, Poly Cord Crimps, Lug Connections, Connectors, Electric Connectors, Electric Wire & Cable Connectors, Wire Connectors, Cordage Crimps, Electronic Hardware, Fasteners, Automotive Fasteners, Strain Relief Grips, Lanyard Hooks, Cable & Wire Lugs, Electrical Lugs, Cable Splices, Metal Stampings, Strain Reliefs, Webbing Fastener.

Approximate Diameter >> in [Imperial]:

0.140

Length >> in [Imperial]:

0.205

Material:

Brass

Minimum Order:

1

Thickness >> in [Imperial]:

0.020

Made in the U.S.A. since 1946. An ISO9001 Certified Manufacturer of Metal Stampings including Ear Band Strain Reliefs.

These specially designed Ear Band Strain Reliefs are manufactured from Brass and Steel. The Ear Band is a “U” Shaped Crimp with Ears located on the Top of the Crimp. The Ear Bands can be used on electrical cord, poly cord, electronic cable & wire to increase the cord diameter, to mold over, prevent pull thru, and to anchor assemblies. These Ear Band Strain Reliefs can accommodate cord, cable and wire diameters from 0.100” to 0.437”. Available Options From: In Stock Inventory, In House Tooling for Production Runs, Samples Applied for Prototyping, New Tooling to Produce Your Custom Part Requirements and Custom Application Equipment to meet your Job Specifications.

Ear Band Strain Reliefs are used as; Automotive Parts, Band Clamps, Cable Clamps, Clasps, Clips, Crimps, Bungee Cord Crimps, Poly Cord Crimps, Lug Connections, Connectors, Electric Connectors, Electric Wire & Cable Connectors, Wire Connectors, Cordage Crimps, Electronic Hardware, Fasteners, Automotive Fasteners, Strain Relief Grips, Lanyard Hooks, Cable & Wire Lugs, Electrical Lugs, Cable Splices, Metal Stampings, Strain Reliefs, Webbing Fastener.

These specially designed Ear Band Strain Reliefs are manufactured from Brass and Steel. The Ear Band is a “U” Shaped Crimp with Ears located on the Top of the Crimp. The Ear Bands can be used on electrical cord, poly cord, electronic cable & wire to increase the cord diameter, to mold over, prevent pull thru, and to anchor assemblies. These Ear Band Strain Reliefs can accommodate cord, cable and wire diameters from 0.100” to 0.437”. Available Options From: In Stock Inventory, In House Tooling for Production Runs, Samples Applied for Prototyping, New Tooling to Produce Your Custom Part Requirements and Custom Application Equipment to meet your Job Specifications.

Ear Band Strain Reliefs are used as; Automotive Parts, Band Clamps, Cable Clamps, Clasps, Clips, Crimps, Bungee Cord Crimps, Poly Cord Crimps, Lug Connections, Connectors, Electric Connectors, Electric Wire & Cable Connectors, Wire Connectors, Cordage Crimps, Electronic Hardware, Fasteners, Automotive Fasteners, Strain Relief Grips, Lanyard Hooks, Cable & Wire Lugs, Electrical Lugs, Cable Splices, Metal Stampings, Strain Reliefs, Webbing Fastener.

Approximate Diameter >> in [Imperial]:

0.140

Length >> in [Imperial]:

0.205

Material:

Brass

Minimum Order:

1

Thickness >> in [Imperial]:

0.020

Made in the U.S.A. since 1946. An ISO9001 Certified Manufacturer of Metal Stampings including Ear Band Strain Reliefs.

These specially designed Ear Band Strain Reliefs are manufactured from Brass and Steel. The Ear Band is a “U” Shaped Crimp with Ears located on the Top of the Crimp. The Ear Bands can be used on electrical cord, poly cord, electronic cable & wire to increase the cord diameter, to mold over, prevent pull thru, and to anchor assemblies. These Ear Band Strain Reliefs can accommodate cord, cable and wire diameters from 0.100” to 0.437”. Available Options From: In Stock Inventory, In House Tooling for Production Runs, Samples Applied for Prototyping, New Tooling to Produce Your Custom Part Requirements and Custom Application Equipment to meet your Job Specifications.

Ear Band Strain Reliefs are used as; Automotive Parts, Band Clamps, Cable Clamps, Clasps, Clips, Crimps, Bungee Cord Crimps, Poly Cord Crimps, Lug Connections, Connectors, Electric Connectors, Electric Wire & Cable Connectors, Wire Connectors, Cordage Crimps, Electronic Hardware, Fasteners, Automotive Fasteners, Strain Relief Grips, Lanyard Hooks, Cable & Wire Lugs, Electrical Lugs, Cable Splices, Metal Stampings, Strain Reliefs, Webbing Fastener.

These specially designed Ear Band Strain Reliefs are manufactured from Brass and Steel. The Ear Band is a “U” Shaped Crimp with Ears located on the Top of the Crimp. The Ear Bands can be used on electrical cord, poly cord, electronic cable & wire to increase the cord diameter, to mold over, prevent pull thru, and to anchor assemblies. These Ear Band Strain Reliefs can accommodate cord, cable and wire diameters from 0.100” to 0.437”. Available Options From: In Stock Inventory, In House Tooling for Production Runs, Samples Applied for Prototyping, New Tooling to Produce Your Custom Part Requirements and Custom Application Equipment to meet your Job Specifications.

Ear Band Strain Reliefs are used as; Automotive Parts, Band Clamps, Cable Clamps, Clasps, Clips, Crimps, Bungee Cord Crimps, Poly Cord Crimps, Lug Connections, Connectors, Electric Connectors, Electric Wire & Cable Connectors, Wire Connectors, Cordage Crimps, Electronic Hardware, Fasteners, Automotive Fasteners, Strain Relief Grips, Lanyard Hooks, Cable & Wire Lugs, Electrical Lugs, Cable Splices, Metal Stampings, Strain Reliefs, Webbing Fastener.

Approximate Diameter >> in [Imperial]:

0.160 x 0.060

Length >> in [Imperial]:

0.205

Material:

Brass

Minimum Order:

1

Thickness >> in [Imperial]:

0.020

Made in the U.S.A. since 1946. An ISO9001 Certified Manufacturer of Metal Stampings including Ear Band Strain Reliefs.

These specially designed Ear Band Strain Reliefs are manufactured from Brass and Steel. The Ear Band is a “U” Shaped Crimp with Ears located on the Top of the Crimp. The Ear Bands can be used on electrical cord, poly cord, electronic cable & wire to increase the cord diameter, to mold over, prevent pull thru, and to anchor assemblies. These Ear Band Strain Reliefs can accommodate cord, cable and wire diameters from 0.100” to 0.437”. Available Options From: In Stock Inventory, In House Tooling for Production Runs, Samples Applied for Prototyping, New Tooling to Produce Your Custom Part Requirements and Custom Application Equipment to meet your Job Specifications.

Ear Band Strain Reliefs are used as; Automotive Parts, Band Clamps, Cable Clamps, Clasps, Clips, Crimps, Bungee Cord Crimps, Poly Cord Crimps, Lug Connections, Connectors, Electric Connectors, Electric Wire & Cable Connectors, Wire Connectors, Cordage Crimps, Electronic Hardware, Fasteners, Automotive Fasteners, Strain Relief Grips, Lanyard Hooks, Cable & Wire Lugs, Electrical Lugs, Cable Splices, Metal Stampings, Strain Reliefs, Webbing Fastener.

These specially designed Ear Band Strain Reliefs are manufactured from Brass and Steel. The Ear Band is a “U” Shaped Crimp with Ears located on the Top of the Crimp. The Ear Bands can be used on electrical cord, poly cord, electronic cable & wire to increase the cord diameter, to mold over, prevent pull thru, and to anchor assemblies. These Ear Band Strain Reliefs can accommodate cord, cable and wire diameters from 0.100” to 0.437”. Available Options From: In Stock Inventory, In House Tooling for Production Runs, Samples Applied for Prototyping, New Tooling to Produce Your Custom Part Requirements and Custom Application Equipment to meet your Job Specifications.

Ear Band Strain Reliefs are used as; Automotive Parts, Band Clamps, Cable Clamps, Clasps, Clips, Crimps, Bungee Cord Crimps, Poly Cord Crimps, Lug Connections, Connectors, Electric Connectors, Electric Wire & Cable Connectors, Wire Connectors, Cordage Crimps, Electronic Hardware, Fasteners, Automotive Fasteners, Strain Relief Grips, Lanyard Hooks, Cable & Wire Lugs, Electrical Lugs, Cable Splices, Metal Stampings, Strain Reliefs, Webbing Fastener.

Approximate Diameter >> in [Imperial]:

0.125

Length >> in [Imperial]:

0.310

Material:

Brass

Minimum Order:

1

Thickness >> in [Imperial]:

0.020

Made in the U.S.A. since 1946. An ISO9001 Certified Manufacturer of Metal Stampings including Ear Band Strain Reliefs.

These specially designed Ear Band Strain Reliefs are manufactured from Brass and Steel. The Ear Band is a “U” Shaped Crimp with Ears located on the Top of the Crimp. The Ear Bands can be used on electrical cord, poly cord, electronic cable & wire to increase the cord diameter, to mold over, prevent pull thru, and to anchor assemblies. These Ear Band Strain Reliefs can accommodate cord, cable and wire diameters from 0.100” to 0.437”. Available Options From: In Stock Inventory, In House Tooling for Production Runs, Samples Applied for Prototyping, New Tooling to Produce Your Custom Part Requirements and Custom Application Equipment to meet your Job Specifications.

Ear Band Strain Reliefs are used as; Automotive Parts, Band Clamps, Cable Clamps, Clasps, Clips, Crimps, Bungee Cord Crimps, Poly Cord Crimps, Lug Connections, Connectors, Electric Connectors, Electric Wire & Cable Connectors, Wire Connectors, Cordage Crimps, Electronic Hardware, Fasteners, Automotive Fasteners, Strain Relief Grips, Lanyard Hooks, Cable & Wire Lugs, Electrical Lugs, Cable Splices, Metal Stampings, Strain Reliefs, Webbing Fastener.